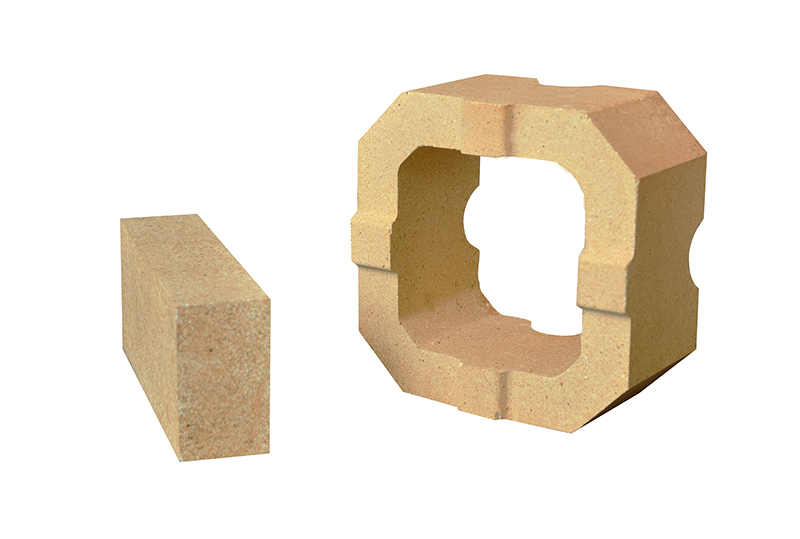

为使窑衬材料充分发挥效能,确保窑衬材料的使用周期,延长使用寿命,对耐火砖砌筑做了以下规定:

1、仔细清扫窑壳内壁的灰尘及渣屑;

2、窑壳内应平整没有凹凸不平现象;

3、砖与砖之间灰缝控制在

4、胶泥的涂抹要均匀饱满,不要有缺浆现象。均匀的涂抹胶泥,且用砌体搓动胶泥,使胶泥能微量挤出;

5、窑衬的砌筑要平整不能有错台,应力求避免错位、倾斜、灰缝不均、离中、重缝、通缝、张口、脱空、毛缝、蛇形弯、砌体鼓包以及混浆等通病;

6、耐火砖衬中的膨胀缝,必须按设计留设,不得遗漏;

7、重要部位和外形复杂部位的衬里应先进行预砌筑;

8、锁缝要牢固。加工砖时要用切砖机对砖进行精细加工,不得使用手工加工砖;在回转窑内及托砖板下的封顶砖应不小于原砖的70%;在平面的接头砖和弯道砖中,不得小于原砖的1/2。必须用原砖锁口。砖的加工面不宜朝向炉膛内侧。

9、耐火材料必须在干燥库房内存放。

河南耐火材料厂 http://www.zzhoudd.com

The instruction of the refractory bricks’s masonry In order to make the materical of kiln liner function fully and ensure its turnaround, prolong service life, making following provisions for the masonry: 1、Sweep carefully the dust and crumbs on the inside wall of kiln shell. 2、Inside wall of kiln shell should be level up and no irregularity phenomenon. 3、The mortar joint between brick and brick is controlled 4、Mortar smear should be even and full. Don’t hane thelack of the mortar phenomenon. You should smear well the mortar.And you twist mortar with brickwork to extrude a litter mortar. 5、Masonry of kiln liner must be level up and no slab staggering .You should do your best to avoid malposition, lean, mortar joint uniformity, decentring, hemstitch, straight joint, yawn, bursted, raw seam, warp form the shape of the snake, humping and the mortar is unwell, etc are common faults. 6、According to design, the expansion gap of firebrick must remain. You cannot omit. 7、You should masonry in advance in important and complex outline part of the klin lining. 8、Firm whipstich.You must process finely brick with brick cutter. Don’t process brick with hand. Neck brick should be larger 70% than other brick. The last brick in one plane or the brick in a curve should be larger 50% than other brick. Must foreshaft with the same brick. The machined surface is not suitable to facing the inside hearth. 9、Refractory should be stored in dry warehouse. ZHENGZHOU DENGDA REFRACTORY CO.,LTD 27 2024-04 02 2023-09 22 2023-08 22 2023-08 23 2022-11 16 2022-07 13 2022-07 11 2022-06 30 2022-05

相关资讯

热门产品